Manufacturing professionals, still struggling with wire harness welding challenges? It’s time for ultrasonic wire harness welding technology to open a new world for you!

一、Painful !Have You Stepped into the Traps of Traditional Welding?

- “False Welding & Missing Welding: Orders Down the Drain”

Traditional welding lacks stability—one oversight leads to false or missing welds. Products fail inspection and get scrapped, while customer 催单 (urgent order) calls flood in! - “Time-Consuming & Costly: Budget Explosion”

Manual welding is as slow as a snail. During peak seasons, you have to hire endlessly, with wages and overtime piling up—eating away at profits! - “Material Limitations: Business Expansion Blocked”

For special materials like copper and aluminum wires, traditional welding either fails to bond securely or damages the wires, making it impossible to expand into new markets!

二、Ultrasonic Welding: A “Game-Changing Strike”!

1. Welding Quality “Stable as a Rock”

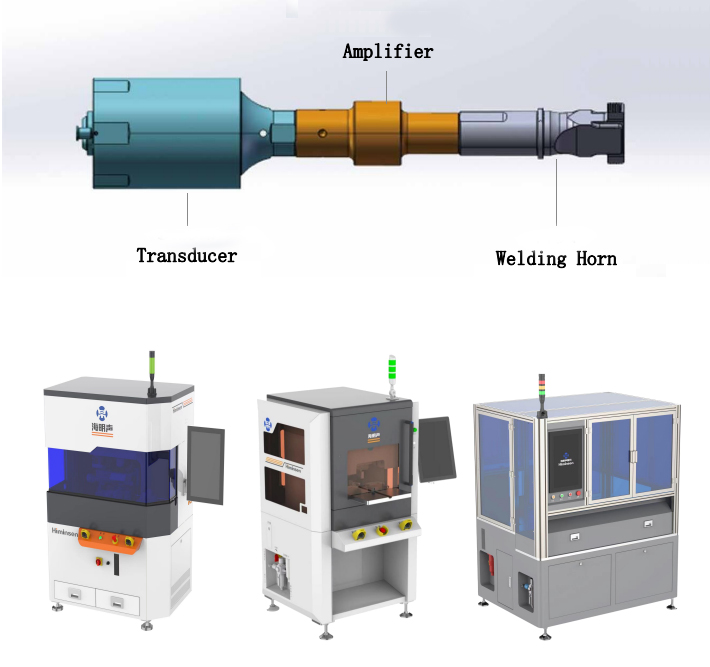

Ultrasonic welding uses high-frequency vibration friction to generate heat, creating uniform and 牢固 (secure) welds. It works on copper, aluminum, multi-strand thin wires, etc.—saying goodbye to false and missing welds! Product inspection pass rates soar, customers are fully satisfied, and orders are locked in!

2. Efficiency “Skyrockets”, Costs “Plummet”

With automatic welding mode, it completes one weld in seconds—finishing in hours what traditional welding takes half a day! No need to hire excessively; labor costs are cut by half, while production capacity doubles. No more panic during peak seasons—profits surge💸!

3. Material Adaptability “Super Versatile”

Whether it’s copper, aluminum, multi-strand thin wires, or non-standard wires, ultrasonic welding adapts perfectly without damaging wire performance. Easily expand into high-end businesses! Automotive, home appliances, communications… Enter any industry with this technology✨!

三. Who Uses It Wins Big!

After adopting ultrasonic wire harness welding:

✅ 0 welding defects—major clients tripled orders, making competitors green with envy!

✅ Efficiency increased by 300%, labor costs dropped to ¥30,000, and profits doubled!

✅ Leveraging technical advantages, they entered the high-end new energy vehicle supply chain—orders booked until next year!

4、Exclusive Benefits for Manufacturers!

DM (Direct Message) us with 【Ultrasonic Welding】 to get:

- 《Ultrasonic Wire Harness Welding Technology Application Manual》 (industry adaptation plans + cost calculation sheets)

- Limited-time booking for a free technical demo—see the equipment’s performance firsthand before deciding!

- Chance to win a 【Manufacturing Process Upgrade Pack】 (peer cost-cutting cases + equipment procurement anti-scam guide) for 5 lucky winners!

Don’t let traditional welding hold you back! With ultrasonic wire harness welding, master efficiency, quality, and profits—become the industry “King of Growth” next year🔥!

#UltrasonicWelding #ManufacturingUpgrade #WireHarnessProcessing #CostReduction #ProductionRevolution编辑分享

📩For more information, please feel free to contact us:

📧Email: delin@himinsens.com

📞Tel: +8618938694287

📍Address: 101, Building 8, Jin’an Building, Shangcun, Gongming Street, Guangming District, Shenzhen

#Ultrasonic terminal welding machine#WeldingEquipment #Industrial Goods