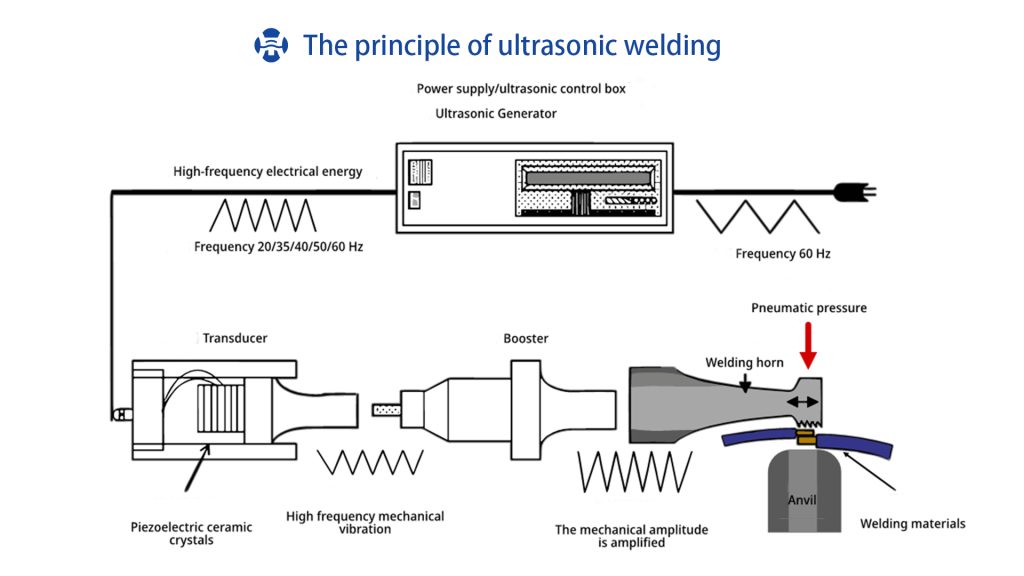

The principle of ultrasonic wire harness welding is as follows:

Ultrasonic generators convert mains electricity into high-frequency and high-voltage alternating current and supply it to ultrasonic transducers. The transducer converts electrical energy into mechanical energy, that is, ultrasonic waves. The manifestation is that the transducer makes a reciprocating telescopic movement longitudinally. The frequency of this telescopic movement is equal to the frequency of the high-frequency alternating current supplied by the driving power supply. When the ultrasonic vibration passes through the welding area, due to the large acoustic resistance at the welding area, that is, the interface between the two welds, local high temperature will be generated. Also, due to the poor thermal conductivity of plastics, it cannot be dissipated in time. It accumulates in the welding area, causing the contact surfaces of the two plastics to melt quickly. With a certain pressure, they are fused into one. After the ultrasonic wave stops acting, let the pressure last for a few seconds to make it solidify and form. In this way, a strong molecular chain is formed to achieve the purpose of welding.

Now, let’s understand the welding principle with the picture.