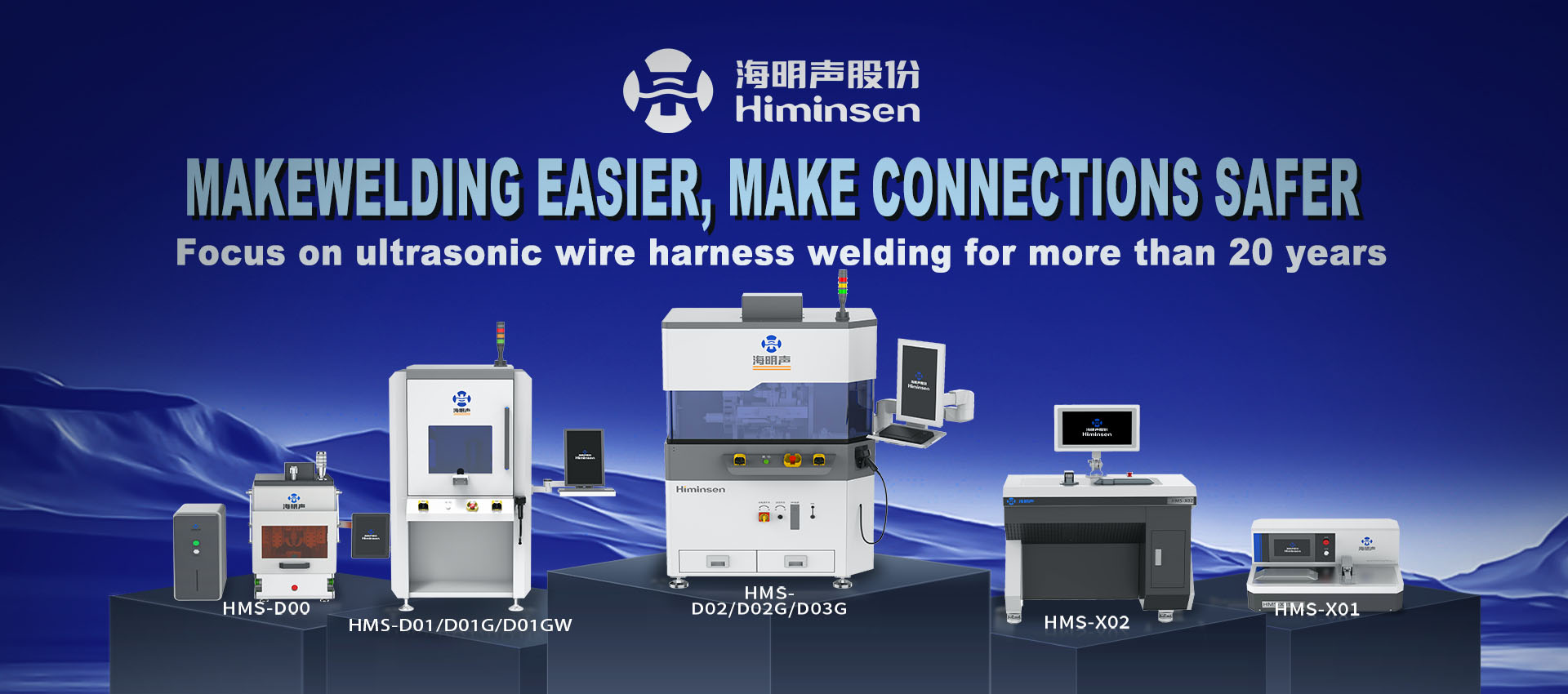

Himinsen Ultrasonic Wire Harness Welding machine

Technical Core: Why Can Ultrasonic Welding Break Through the Limitations of Traditional Connections?

1.1 Welding Stability: From “Manual Dependence” to “Digital Control”

1.2 Material Compatibility: Covering the Needs of Multi-Specification and Multi-Material Wire Harnesses

- For thin-diameter wire harnesses (e.g., microcurrent transmission wires in medical devices), titanium alloy micro-welding heads are adopted to avoid wire harness breakage during welding;

- For oxidation-prone materials like aluminum wires, the ultrasonic vibration breaks the oxide film without the need for additional flux, reducing the risk of corrosion at connection points;

- It supports parallel welding of multi-strand wire harnesses (up to 30 strands can be welded simultaneously), and the cross-sectional area of the welded joint is reduced by 30%, making it suitable for space-constrained scenarios such as new energy vehicle battery packs.

1.3 Balance Between Safety and Efficiency: Meeting the Requirements of High-Beat Production

2.1 R&D Strength: Driven by Both Patents and Industry-University-Research Cooperation

- Technical Patents: Accumulated 18 patents related to ultrasonic welding, among which 3 patents such as “adaptive frequency tracking algorithm” and “multi-material compatible welding head design” are industry-first, solving the problem of “difficult material adaptation” in traditional welding;

- Industry-University-Research Cooperation: Co-established the “Ultrasonic Connection Technology Joint Laboratory” with the School of Materials Science and Engineering of Shanghai Jiao Tong University to conduct pre-research on connection technologies for extreme scenarios such as aerospace and deep-sea equipment. Currently, the wire harness welding technology verification under 1000-meter deep-sea water pressure has been completed;

- Standard Participation: Participated in the formulation of “Technical Requirements for Ultrasonic Welding of Industrial Wire Harnesses” (GB/T XXXXX-2025), becoming one of the core drafting units of industry technical standards.

2.2 Production and Quality Control: Global Layout Ensures Delivery Capacity

- Manufacturing System: Has three major production bases in China (Suzhou), Germany (Munich), and Japan (Nagoya), equipped with ISO 9001/14001 dual-system certified production lines, enabling “local production and rapid delivery” – the delivery cycle for European customer orders can be shortened to 7 days at the shortest;

- Quality Inspection: Each device undergoes 1000 consecutive welding tests, high-low temperature cycle tests (-40℃~85℃), and electromagnetic compatibility tests (EMC Class B) before leaving the factory to ensure stability under different working conditions;

- Supply Chain Guarantee: Core components (such as ultrasonic transducers and servo motors) adopt imported brands (Swiss Branson, Japanese Yaskawa), and a 90-day inventory early warning mechanism is established to avoid delivery impacts caused by supply chain fluctuations.

2.3 Service System: From Solution Design to Lifelong Support

- Pre-Consultation: Provides free “wire harness connection feasibility assessment”, and outputs customized welding solutions and prototype test reports by simulating customer usage scenarios (such as current, temperature, vibration frequency);

- On-Site Support: After equipment delivery, dispatches technical engineers to conduct on-site installation, commissioning, and operation training (covering operators and maintenance personnel) to ensure rapid production line commissioning;

- Lifelong Service: Customers who purchase equipment can enjoy lifelong technical support, including software upgrades (2 free updates per year), rapid spare parts supply (5 global spare parts centers, delivery within 48 hours), and regular on-site inspections (1 free maintenance per year).

Three Reasons to Choose Himinsen: More Than “Welding Equipment”, But a “Connection Safety Partner”

- Compliance Guarantee: All solutions have passed authoritative certifications corresponding to the industry (such as medical ISO 13485, automotive IATF 16949, aerospace AS9100), helping customers quickly pass the supplier audits of downstream manufacturers;

- Full-Life Cycle Cost Optimization: Although the initial investment of the equipment is higher than that of traditional welding solutions, in the long run, it can reduce maintenance costs by 50% (no wearing parts replacement) and reduce defective product rework costs by 80%, with an average return on investment period of 1.5 years;

- Technical Forward-Looking: Targeting the future industrial needs of “higher integration” and “more extreme environments”, Himinsen has launched the R&D of the next-generation ultrasonic welding technology (such as laser-ultrasonic hybrid welding, AI adaptive control), ensuring that customers’ connection solutions remain leading in the long term.