Precision & Efficiency for EV Cable Manufacturing

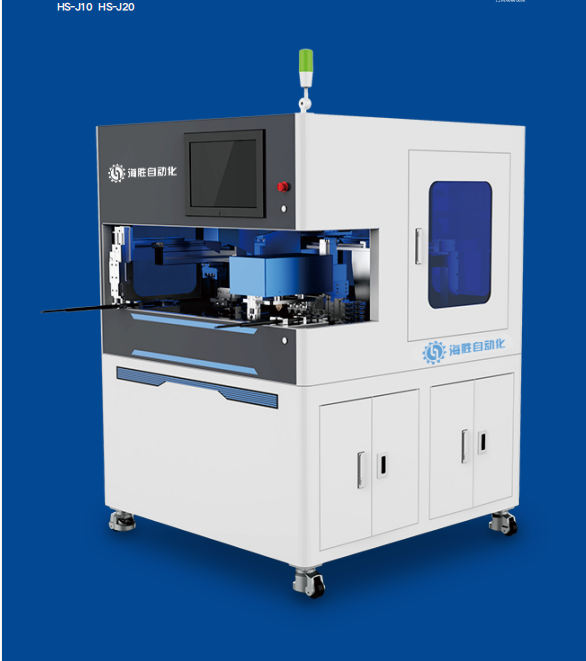

HS-J10_20

⚙️ Key Features

- Industrial HMI Operation: An intuitive, user-friendly interface for full control and monitoring.

- High-Precision Servo Drive: Ensures accurate, repeatable processing for every cable.

- Terminal Tray Sequential Feeding: Maintains a smooth, continuous production flow.

- Pressure Data Monitoring: Real-time feedback on crimping pressure for reliable connections.

- Parameter Storage & Recall: Instantly save and retrieve settings for different cable types.

- MES Integration: Seamlessly connects to your manufacturing execution system for production traceability and management.

🛠️ Step-by-Step Processing

- Core Cable Cutting – Precisely cuts cores to uniform lengths for consistent assembly.

- Core Cable Stripping – Removes insulation with high accuracy to expose conductors.

- Heat-Shrink Tubing Application – Applies and secures protective tubing.

- Terminal Crimping – Creates strong, reliable electrical connections.

📊 Why Choose Our Machine?

EV charging cable processing machine, single/double-end cable crimping machine, 11-axis servo EV cable system, HIMINSEN EV manufacturing equipment, fully automated cable stripping machine, MES-integrated cable processing, high-precision EV cable terminal crimping, core cable cutting and stripping machine