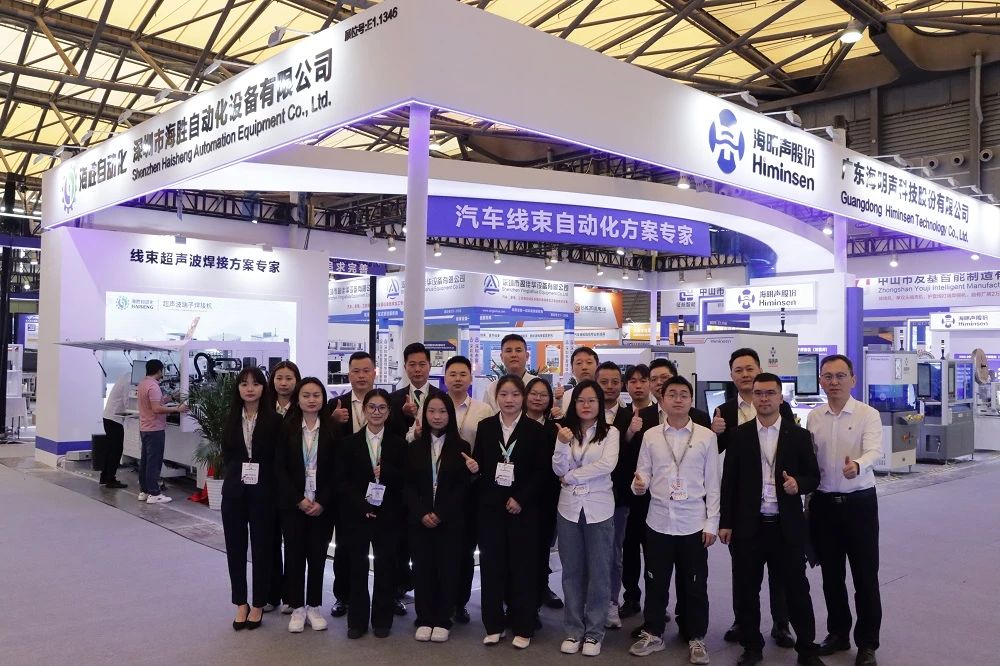

As a vane in the Asian electronics manufacturing industry, the Productronica China 2025 will grandly kick off at the Shanghai New International Expo Center from March 26th to 28th, 2025. The scale of this year’s exhibition reaches nearly 100,000 square meters, gathering over 1,000 top global enterprises and covering the entire industrial chain such as wire harness processing and automated manufacturing. Among them, the core exhibition area of wire harness processing and connector manufacturing in Hall E1 will focus on technological breakthroughs in popular fields such as new energy and automotive electronics. The booth of Haimingsheng (E1.1346) will make a significant appearance as the “pioneer of ultrasonic welding technology”.

Introduction of the Selling Points of the Equipment

1. HMS-D01GW Ultrasonic Terminal Welding Machine (Welding/Pressing All-in-One Machine, with a power of 9000W): Specializes in welding copper/aluminum wire harnesses with a cross-sectional area of 6-95 square millimeters for new energy vehicles. It features the original synchronous welding and pressing technology, which solves the problem of virtual soldering in high-voltage wire harnesses. After welding, the resistance coefficient is reduced by 20%.

2. HMS-D01Z Ultrasonic Full-automatic Welding Machine: Integrates unmanned operation of the entire process including wire cutting, stripping, welding, and conveying. The efficiency is increased by 60% compared with traditional processes, and it is suitable for the upgrading needs of industrial automation production lines.

3. HMS-X02 Ultrasonic Wire Harness Welding Machine (with a power of 6000W, capable of welding copper wires with a cross-sectional area of 0.5-50mm², for wire-to-wire welding): For ultra-thin wire harnesses with a cross-sectional area of 0.5mm², the error is controlled within ≤0.1mm, meeting the requirements of high-precision scenarios such as consumer electronics and medical equipment.

Convenient transportation:

You can reach the exhibition hall within a 1-minute walk from Huamu Road Station on Metro Line 7. It is recommended that you bring your original ID card for quick entry.

Registration QR code for visitors