Key Features for Industrial Excellence: Powered by Trends-Driven Innovation

1. Power & Welding Range: Meet Diverse Industrial Demands

- 9000W Ultrasonic Power: Effortlessly welds copper/aluminum wires from 6mm² to 95mm², covering the needs of high-volume production lines in new energy electric vehicles, home appliances, and communication equipment—sectors that have seen rising search interest alongside 2026’s focus on sustainable manufacturing.

- Precision Control via 18.5-Inch Touch Display: Monitor welding time, energy, pressure, amplitude, and pre/post-weld height in real time. This smart control aligns with the global curiosity for “AI-driven process monitoring” (a sub-trend under Google’s top search Gemini AI), ensuring consistent quality without manual errors.

2. Efficiency & Productivity: Keep Up with 2026’s Fast-Paced Production

- High Throughput: Achieve 120–150pcs per hour while maintaining high-strength welds—perfect for industries racing to meet post-pandemic production goals, a key concern in global “industrial productivity” searches this year.

- 100,000 Sets of Data Storage: Ensure repeatability and process traceability, addressing the growing demand for “data-driven manufacturing” (a trend linked to 2026’s AI boom). This feature lets you track every weld, a critical need for compliance in automotive and medical device sectors (both top application areas for wire harnesses, per industry searches).

3. Eco-Friendly & User-Centric Design: Align with Sustainable Trends

- No Additional Materials Needed: Reduce costs and environmental impact with a clean welding solution, cutting down on waste that’s increasingly scrutinized in global sustainability searches.

- Compact & Secure Build: With dimensions 130010002000mm and weight 610kg, it fits seamlessly into modern factories. Password protection and anti-empty welding features prioritize safety—addressing “workplace safety tech” searches that spiked alongside 2026’s industrial safety regulations.

Why Choose HMS-D01G? Because It’s Built for 2026’s Industrial Priorities

Brand Commitment: “MAKE WELDING EASIER, MAKE CONNECTIONS SAFER”

Industry Applications: Targeting 2026’s High-Growth Sectors

- Automotive & New Energy Vehicles: As searches for “electric vehicle manufacturing” surge, the machine’s ability to weld thick copper/aluminum wires supports battery and electrical system production.

- Home Appliances & Electronics: With iPhone 17 topping tech searches in 2026, the demand for precise wire welding in consumer electronics (TVs, computers, smartphones) is higher than ever—and the HMS-D01G delivers.

- Medical Devices & Aerospace: These sectors, where “high-reliability wiring” is a top search term, benefit from the machine’s consistent weld quality and traceability.

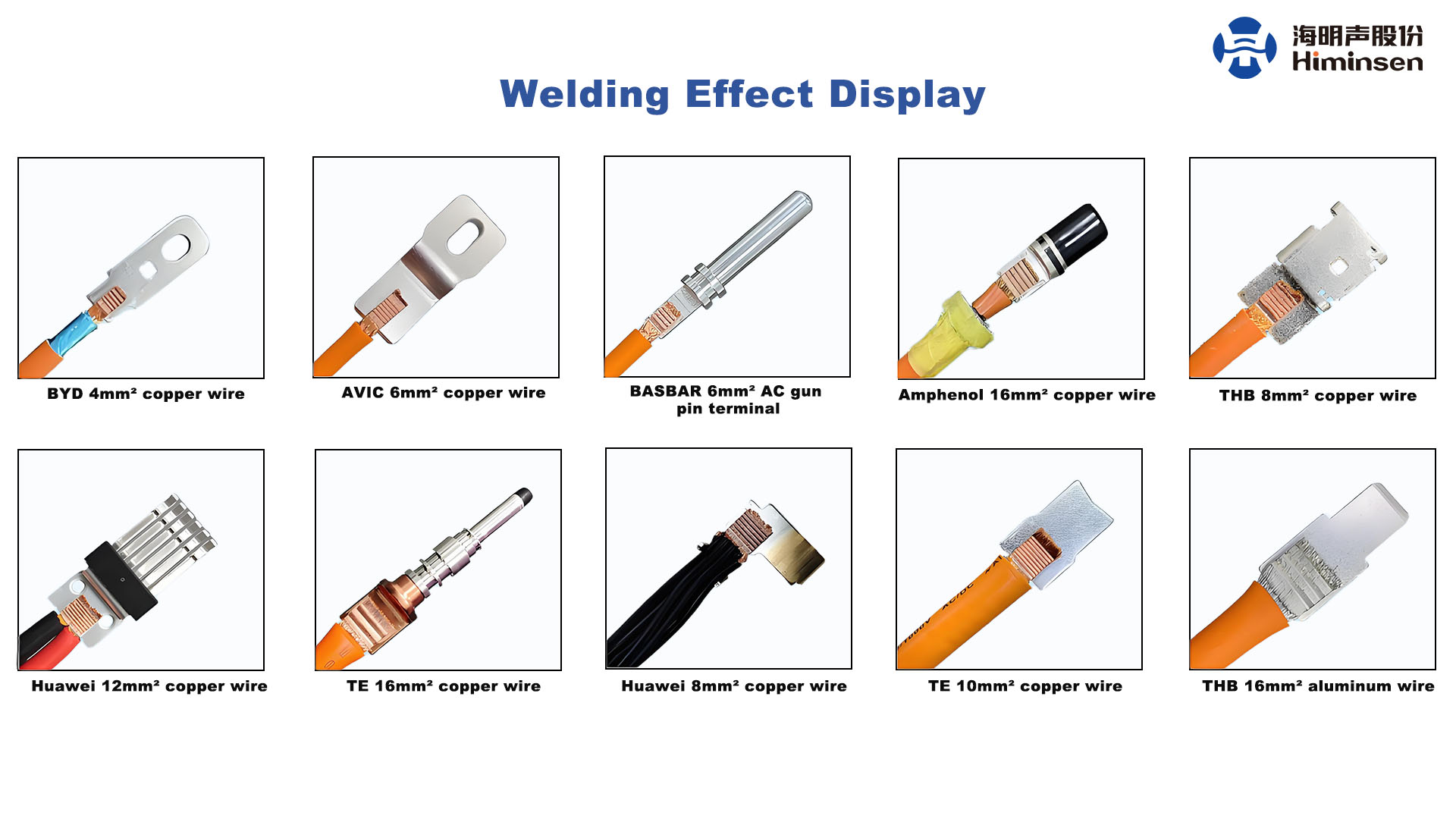

Welding Effect Display

Optimize Your Welding Process—Today

📧Email: delin@himinsens.com

📞Tel: +8618938694287

📍Address: 101, Building 8, Jin’an Building, Shangcun, Gongming Street, Guangming District, Shenzhen, China