Still tearing your hair out over the difficulty of welding multi – material wire harnesses and the challenge of controlling equipment parameters?

An automotive enterprise/electronics factory secretly used it, maximizing the welding efficiency of copper – aluminum wire harnesses and slashing the defect rate to zero!

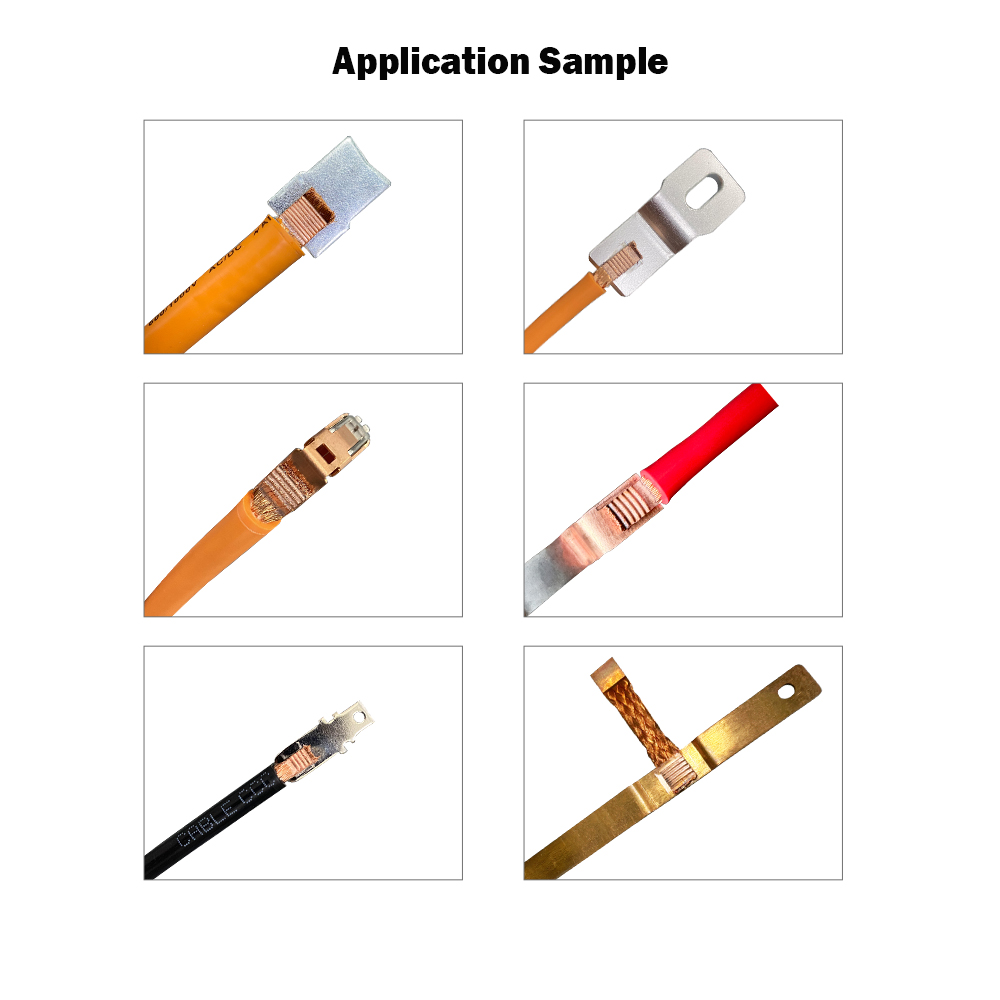

It is the HMS – D00 Ultrasonic Wire Harness Welding Machine — capable of handling 2.5 – 25mm² copper wires + 2.5 – 35mm² aluminum wires with ease. The “hexagonal warrior” in the welding world has arrived!

📏 710*750*830mm + 220kg! A Star in the Workshop

Is the equipment too large and clumsy to arrange?

This “all – rounder in the workshop” has dimensions that fit production lines, and at 220kg, it’s stable and doesn’t take up much space!

It can be flexibly placed in automotive/household appliance production lines, with zero pressure for line change and debugging . No more dismantling workstations or calling in forklifts…

🔥 120 – 150pcs/H! Copper – Aluminum Welding Soars

Is traditional multi – material welding a slow grind?

This machine welds 120 – 150 joints per hour (seamlessly switching between copper and aluminum wires, and stably welding even up to 25/35mm² thicknesses)!

When rushing to meet deadlines for automotive/household appliance/communication wire harnesses, it crushes competitors in multi – material welding efficiency . Bosses see it and place additional orders overnight…

💎 100,000 Sets of Parameter Storage! Welding as Stable as a “Mighty Anchor”

Is welding difficult due to the large differences between copper and aluminum materials?

It can precisely store 100,000 sets of welding parameters , automatically adapting to copper – aluminum welding!

An automotive enterprise used it, and its copper – aluminum wire harnesses withstood 500,000 vibration tests without breaking . Competitors are still guessing, “What on earth makes it weld so stably?”

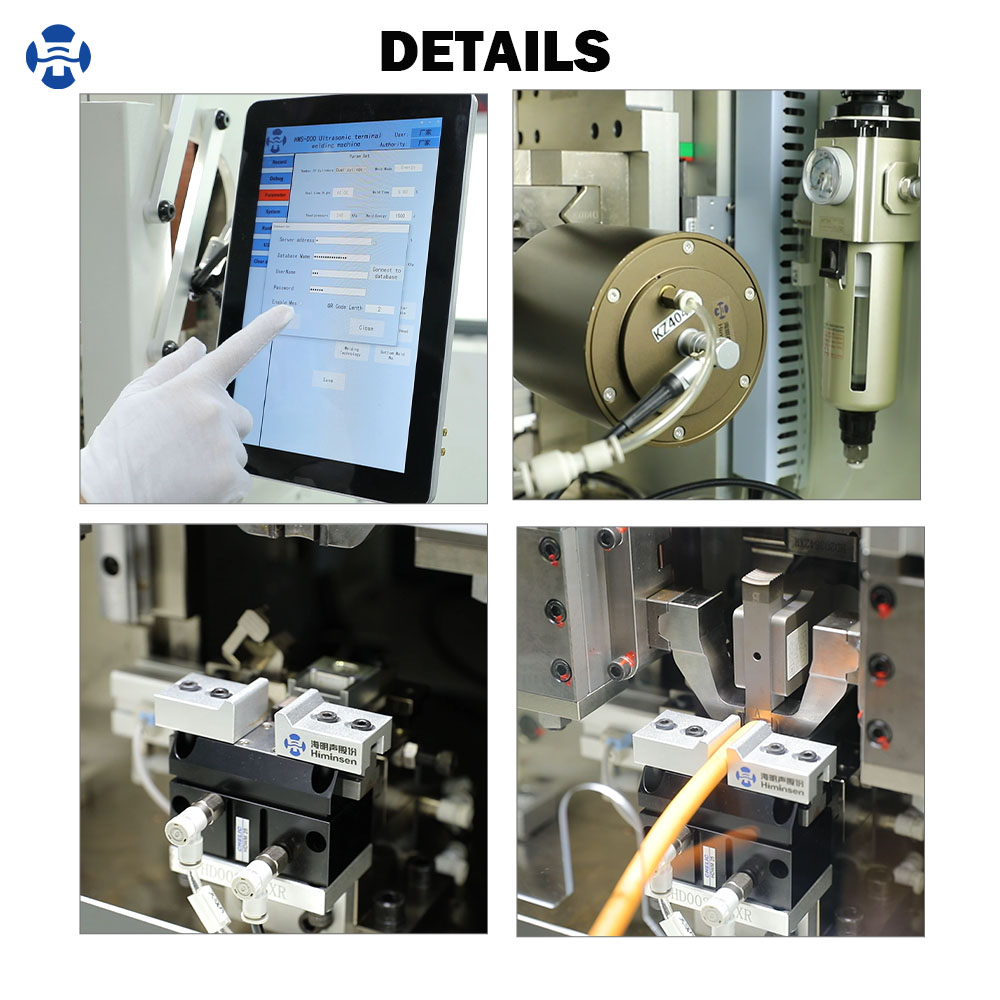

🤯 10.1 – inch Touchscreen! Parameter Adjustment with Zero Threshold

Can new employees not adjust parameters?

The 10.1 – inch large screen real – time displays welding time/energy/pressure , with password protection for extra security!

New factory workers learn to control parameters in 10 minutes . No more spending a fortune on training. HR directly uses it as a “retention ”…

🔍 Interactive Guessing Game!

(The list of cooperating customers has hidden surprises)

Guess! Which top – tier automotive enterprise/electronics factory secretly switched to this “All – Round Welding Champion”?

The 5th, 10th, and 15th correct guesses in the comments will directly receive the “Copper – Aluminum Wire Harness Welding Process Manual” (including welding solutions for multiple industries)!

Want to supercharge the efficiency and quality of copper – aluminum welding?

Click now

The revolution in multi – material welding starts with this “All – Round Welding Champion”!

📩For more information, please feel free to contact us:

📧Email: delin@himinsens.com

📞Tel: +8618938694287

📍Address: 101, Building 8, Jin’an Building, Shangcun, Gongming Street, Guangming District, Shenzhen

#WireHarnessWelding #IndustrialInnovation #FactoryEfficiency #NewEnergyVehicles #CostReduction#Ultrasonic terminal welding machine