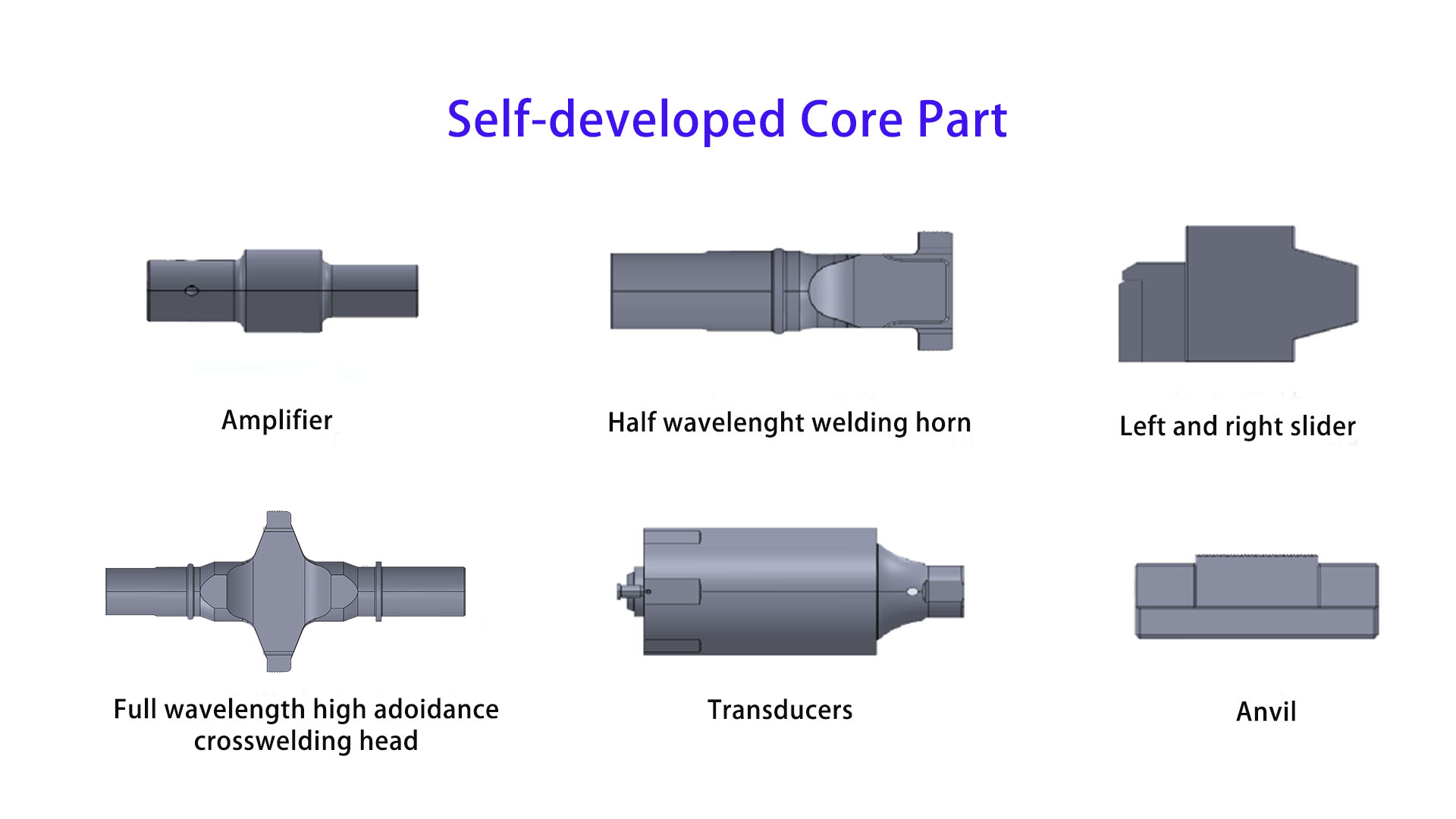

In the realm of ultrasonic welding, while welding machines often take the spotlight, there’s a core component working tirelessly behind the scenes to ensure precision, efficiency, and reliability — the ultrasonic welding horn. As a self-developed key part of Himinsen’s welding equipment, this “unsung hero” is the backbone of seamless and high-quality welding operations.

Himinsen’s ultrasonic welding horn is engineered to perform two critical roles that define welding success:

-

Ultrasonic Energy Transmission: It accurately channels ultrasonic energy directly to the welding zone, ensuring optimal energy conversion for consistent, strong welds.

-

Controlled Pressure Application: While delivering energy, the horn applies precise, appropriate pressure to forge tight, durable bonds between terminals and wires, eliminating loose connections and ensuring long-term stability.

Crafted in a range of shapes and sizes, Himinsen’s welding horns are designed for maximum compatibility. They seamlessly adapt to various specifications of terminals and wires, making them indispensable across key industries:

-

Automotive manufacturing

-

Electronics and electrical equipment production

-

Aerospace engineering

-

And other precision manufacturing sectors

Beyond compatibility, these horns excel in precise welding position control. This not only guarantees uniform welding quality but also enhances the overall reliability and stability of the final products — a non-negotiable requirement in high-stakes industries.

Rooted in Himinsen’s core brand concept, “MAKE WELDING EASIER, MAKE CONNECTIONS SAFER,” every ultrasonic welding horn is built to deliver three key advantages:

-

High Performance: Ensures efficient energy transfer and consistent welding results, even in demanding production environments.

-

High Reliability: Undergoes rigorous testing to withstand continuous industrial use, minimizing downtime and maintenance costs.

-

High Adaptability: Customizable shapes and sizes to meet the unique needs of different welding tasks and industry standards.

By integrating this self-developed core component into its welding equipment, Himinsen continues to empower industries worldwide to elevate their welding technology, driving innovation and excellence in the field of ultrasonic welding.

Whether you’re seeking a compatible welding horn for your existing equipment or exploring customized solutions, our team is ready to assist:

- 邮箱:delin@himinsens.com

- Tel: +86 18938694287

- Address: 101, Building 8, Jin’an Building, Shangcun Community, Gongming Street, Guangming District, Shenzhen, China

#UltrasonicWeldingHorn #Himinsen #CoreComponent #WeldingPrecision #IndustrialManufacturing #UltrasonicWelding #SelfDevelopedTechnology #WeldingEquipmentParts