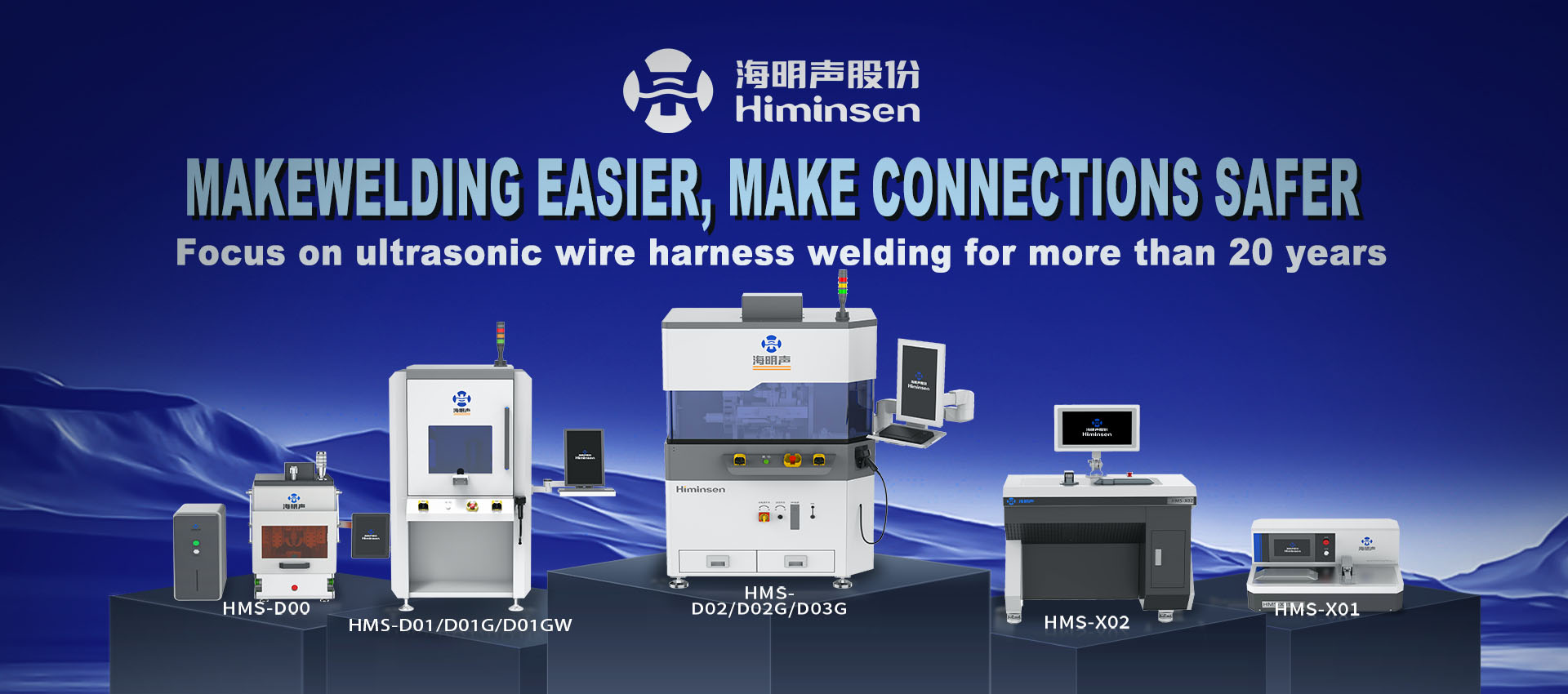

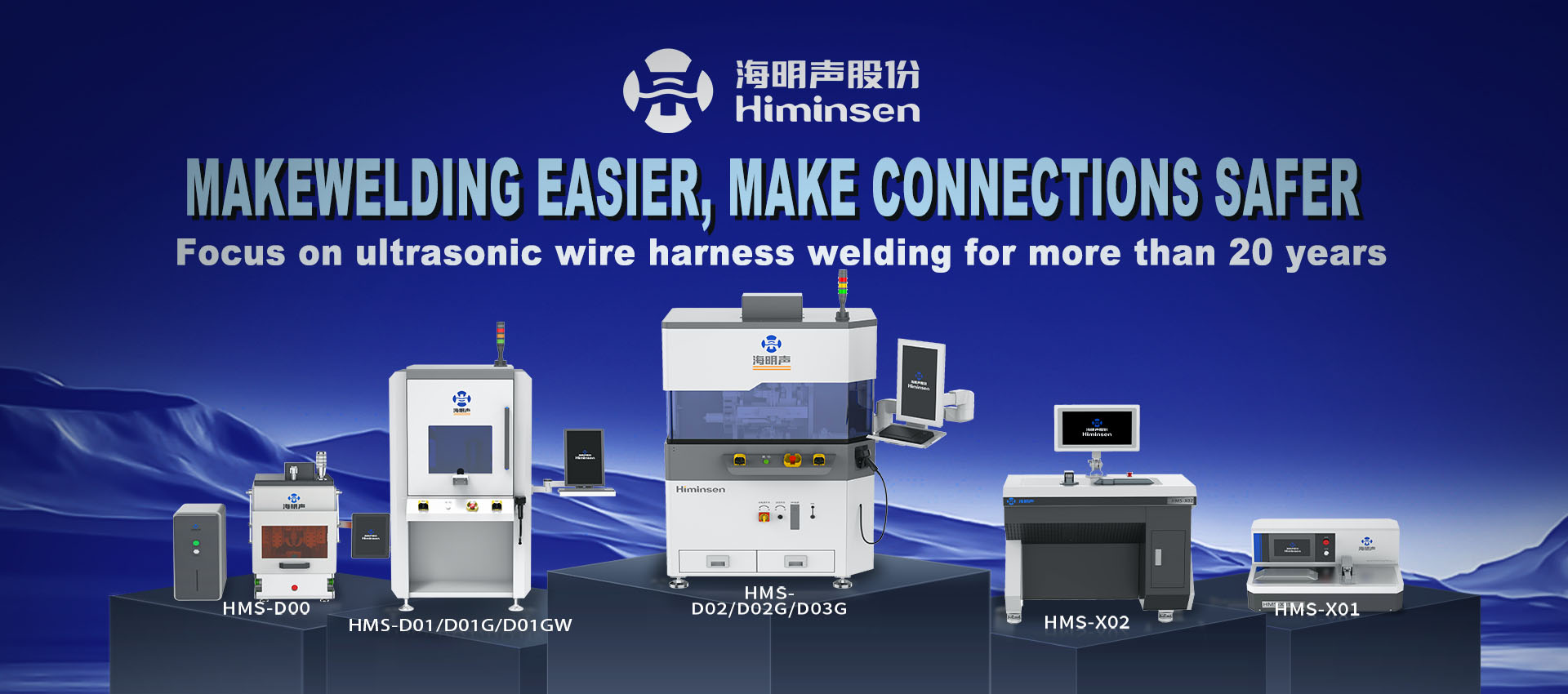

In the realm of wire harness manufacturing, Himinsen leads with self-developed equipment including ultrasonic welding machines, terminal crimping machines, wire cutting and stripping machines, and tube cutters. Engineered for efficiency, precision, and reliability, our solutions redefine productivity across automotive, electronics, and industrial sectors.

HS-JY1.5T Silent terminal machine

HS-15025 coaxial cutting and stripping machine

- R&D Leadership: All equipment is self-developed, integrating advanced technology for process control and user-friendliness.

- Customer-Centric Service: From sampling to mass production, we support tailored solutions and rapid prototyping.

- Global Application: Trusted in vehicles, instruments, communication devices, and household appliances worldwide.

Ready to transform your wire harness processing? Contact Himinsen today for a customized solution or sample test.

📩For more information, please feel free to contact us:

📧Email: delin@himinsens.com

📞Tel: +8618938694287

📍Address: 101, Building 8, Jin’an Building, Shangcun, Gongming Street, Guangming District, Shenzhen,China

#WireProcessing #ProductionEfficiency #AutomationEquipment #Terminal Crimpping Machine

#Himinsen #WireHarnessEquipment #UltrasonicWeldingMachine #TerminalCrimpingMachine #WireCuttingStrippingMachine #TubeCutter #IndustrialEquipment #ManufacturingSolutions