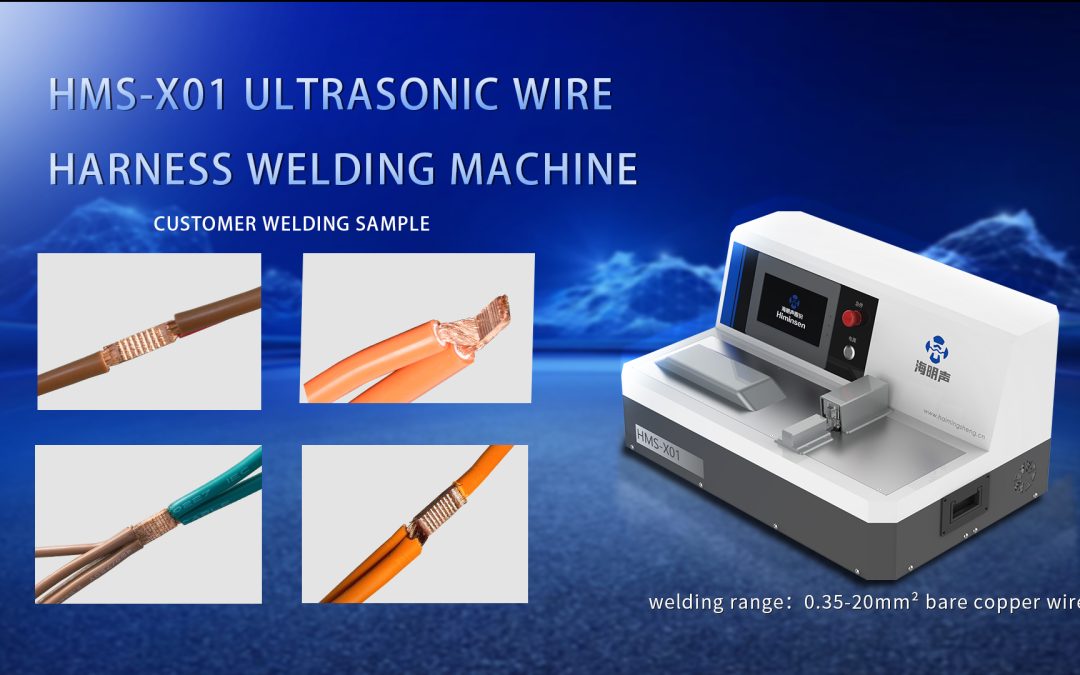

Revolutionize Your Welding Experience: The HMS – X01 Ultrasonic Wire Harness Welding Machine is Here!

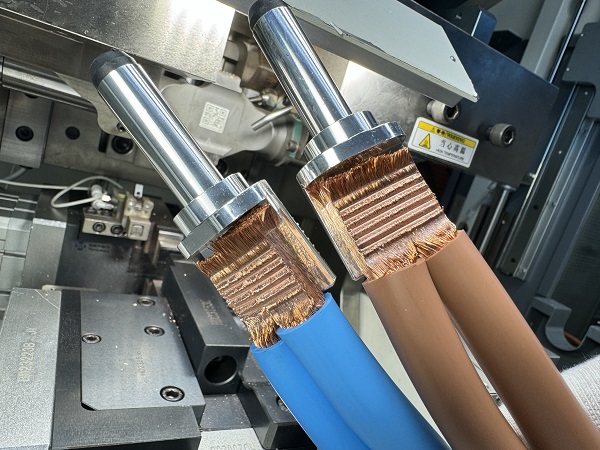

Still troubled by wire harness welding problems? Don't worry! The HMS - X01 ultrasonic wire harness welding machine makes a strong debut to solve your problems! Precise Parameters for Reliable Performance With an input voltage of AC 220V 50Hz and a power of 3000W, it...

High – Efficiency Welding Solution | HMS – X02 Ultrasonic Welding Machine

Still troubled by inefficient welding equipment? Check out the HMS - X02 Ultrasonic Welding Machine! ✨ With an input voltage of AC 220V 50Hz, it's compatible with common power environments. It can easily weld bare copper wires ranging from 0.35mm² to 40mm², and copper...

Innovation – Driven! Self – developed HS – 15025 Coaxial Cable Stripping and Cutting Equipment Debuts

In the field of new energy electronic product processing, continuous innovation and breakthroughs are the driving forces for development. Today, we are proud to introduce a remarkable product that embodies the painstaking efforts of our company's self - developed...

Big News! A Powerful Tool for New Energy Wire Harness Stripping is Here!

With the booming development of the new energy industry, the wire harness stripping process is crucial for production efficiency and quality. Today, we are excited to introduce a remarkable device - the HS - 9018 Coaxial Wire Stripping Machine, specifically designed...

Brand – New Release! A Cutting – Edge Tool for New Energy Cable Manufacturing

In the era of rapid development of new energy, the cable manufacturing process is of utmost importance. Today, we are excited to introduce a device that will revolutionize new energy cable manufacturing - the AC220V 50Hz Single Cable Line Slicing and Peeling...

New Favorite in Industrial Crimping! The HS – SK40T CNC Servo Terminal Crimping Machine is Here!

In modern industrial production, efficient and precise terminal crimping equipment is the key to improving production quality and efficiency. Today, we'd like to introduce you to an outstanding HS - SK40T CNC Servo Terminal Crimping Machine! Despite its large size...

-1080x675.png)

A New Star in the Welding World! Himinsen’s HMS-D00L Ultrasonic Wire Harness Welding Machine Ushers in a New Era of Efficient Welding

In the field of industrial manufacturing, the quality of welding technology directly affects the quality of products and production efficiency. Today, I'm going to introduce you to an innovative ultrasonic wire harness welding machine - HMS - D00L, launched by...

HMS – D01GW Ultrasonic Terminal Welding Machine: The All-round King in the Welding Field

HMS-D01GW ultrasonic terminal welding 🔥The terminator of industry problems! The HMS - D01GW ultrasonic terminal welding machine is equipped with a 9000W high-power system, which can effortlessly handle the welding of copper/aluminum wires ranging from 6 to 95 square...

Why Choose Himinsen Ultrasonic Wire Harness Welding Machine?

HIMINSEN Himinsen are founded by an elite team with over 20 years of experience in industrial ultrasonic applications. We are committed to becoming a global provider of high - quality wiring harness processing equipment and to offering quality services to customers...

The High – efficiency Ultrasonic Wire Harness Welding Machine: Your Ideal Choice

In today's fast - paced industrial production field, the efficiency and precision of wire harness welding are of great significance. Facing complex wire harness welding tasks, are you looking for a device with excellent performance and stable reliability? Our...